In pharmaceutical industries the classified area may be the area in which our drug products and solutions have immediate contact with the air & We have now a Management variety of airborne particles.

Tests and Investigation to make sure that significant devices will function under adverse environmental disorders

Continuous Monitoring: GMP restrictions need stringent and continual monitoring of cleanrooms to maintain an ongoing awareness of environmental situations.

Generally check for the presence of an usually important component from the documentation of your cleaning procedures; identifying and managing the length of time in between the tip of processing and every cleaning action.

Products Malfunction and Non-compliance with Laws: These troubles not simply disrupt cleanroom functions and also pose dangers to product or service integrity and basic safety.

The necessity of extensive teaching of personnel working in controlled environments, which includes aseptic tactics, can not be overemphasized. The environmental checking method, by alone, won't be capable of detect all activities in aseptic processing that would compromise the microbiological quality from the atmosphere.

Although it is important to assessment environmental benefits on The idea of encouraged and specified frequency, It is usually vital to critique final results over extended durations to ascertain regardless of whether traits are existing. Tendencies can be visualized via the development of statistical control charts that include alert and action amounts. The microbial control of controlled environments may be assessed, in part, on The premise of these trend info. Periodic experiences or summaries really should be issued to inform the accountable supervisor.

Isolator— This know-how is employed for a dual intent. One is to safeguard the product or service from contamination within the natural environment, which include personnel, all through filling and closing, and one other is to shield staff from deleterious or poisonous items that are increasingly being produced. Isolator engineering is predicated over the principle of positioning Beforehand sterilized factors (containers/solutions/closures) right into a sterile natural environment. These components remain sterile during the full processing operation, due to the fact no staff or nonsterile classified area validation elements are brought into the isolator. The isolator barrier can be an complete barrier that does not let for interchanges amongst the shielded and unprotected environments. Isolators either can be physically sealed versus the entry of exterior contamination or might be efficiently sealed by the application of constant overpressure. Manipulations of supplies by staff are accomplished by way of utilization of gloves, half-fits, or whole suits. All air getting into the isolator passes through both an HEPA or UPLA filter, more info and exhaust air normally exits as a result of an HEPA-quality filter. Peracetic acid and hydrogen peroxide vapor are generally utilized for the surface area sterilization of the isolator device's inside natural environment. The sterilization of the inside of isolators and all contents are generally validated to the sterility assurance volume of ten

Rinse Samples - Two benefits of using rinse samples are that a bigger surface area might be sampled, and inaccessible methods or ones that can't be routinely disassembled is often sampled and evaluated.

Monitoring may include other distinct characteristics suitable to your cleanroom’s purpose, for example differential stress or air improve premiums.

five µm or larger. When airborne microorganisms are certainly not totally free-floating or solitary cells, they frequently affiliate with particles of ten to 20 µm. Particulate counts as well as microbial counts in just managed environments differ Using the sampling location and also the functions staying done all through sampling. Checking the surroundings for nonviable particulates and microorganisms is a vital control function since they each are essential in attaining product compendial requirements for Particulate Matter and Sterility underneath Injections

As handbook interventions all through operation raise, and as the possible for personnel connection with the solution improves, the relative importance of the environmental monitoring method increases. Environmental monitoring is a lot more essential for products that are aseptically processed than for items that are processed after which you can terminally sterilized.

Isolator devices require rather rare microbiological monitoring. Ongoing total particulate monitoring can provide assurance the air filtration program inside the isolator is Functioning correctly. The methods for quantitative microbiological air sampling described On this chapter might not have ample sensitivity to check the natural environment inside an isolator.

Controlled areas are not merely highly-priced to make but these are definitely also costlier to keep up. Adhering to details must take into account although creating the clean rooms.

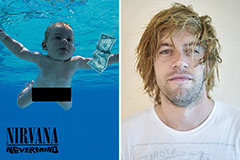

Spencer Elden Then & Now!

Spencer Elden Then & Now! Michael Fishman Then & Now!

Michael Fishman Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now!